Cutting-Edge Weighbridge Solutions for Maximized Efficiency

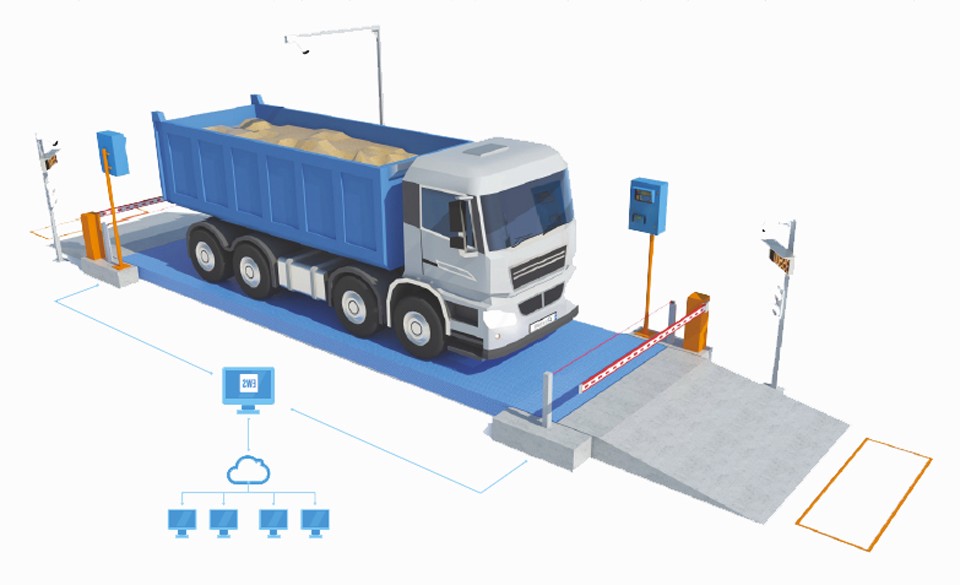

In today's fast-paced transportation industry, efficiency is paramount. Smart weighbridge solutions are revolutionizing the way businesses monitor vehicle loads, leading to significant benefits in operational effectiveness. These systems reduce manual data entry, streamline the weighing process, and generate real-time insights for improved decision-making.

Automated weighbridges are equipped with advanced sensors that precisely measure vehicle weight. This metrics can be connected with other business systems, such as ERP and TMS, for a holistic view of operations. The adoption of automated weighbridge solutions results in numerous benefits, including reduced labor costs, increased throughput, and enhanced safety.

Automated Weighbridges :

In the modern industry/sector/marketplace, efficiency and cost reduction check here are paramount. Unmanned/Automated/Autonomous weighbridges are emerging as a transformative solution, significantly/drastically/substantially improving operational flows/processes/dynamics while greatly/noticeably/considerably reducing labor costs. By leveraging advanced/cutting-edge/sophisticated sensor technology and software/algorithms/systems, these weighbridges can accurately/precisely/reliably measure the weight of vehicles, generate/produce/create detailed reports, and seamlessly/effortlessly/smoothly integrate with existing logistics/transportation/supply chain systems.

- Furthermore/Additionally/Moreover, unmanned weighbridges enhance/boost/improve safety by minimizing/reducing/eliminating the need for human operators to be present/located/positioned in potentially hazardous areas.

- Concurrently/Simultaneously/In tandem, they provide real-time data insights that can optimize/enhance/maximize fleet management, reduce/minimize/decrease fuel consumption, and improve/strengthen/fortify overall operational efficiency.

As a result/Consequently/Therefore, businesses are experiencing/witnessing/observing significant/substantial/considerable benefits from the implementation of unmanned weighbridges, making them an indispensable/essential/vital component of modern transportation/logistics/operations.

Driverless Weighbridge Technology: Enhancing Security and Accuracy

Modern businesses are increasingly implementing manless weighbridge technology to improve both security and accuracy in transactions. These systems leverage detectors and advanced software to streamline the weighing process, minimizing the need for human intervention. Manless weighbridges offer several benefits, including enhanced security through real-time monitoring and minimal chances of tampering. Furthermore, they provide more precise measurements in weighing goods, guaranteeing compliance with industry standards and government regulations.

Transforming Weighing with Automated Systems

In today's fast-paced industrial/manufacturing/operational landscape, accuracy and efficiency/speed/optimization are paramount. Automated weighing systems are revolutionizing/disrupting/transforming the industry by providing precise/accurate/reliable measurements that enhance/improve/boost overall productivity/performance/output. These sophisticated systems utilize cutting-edge technology/sensors/hardware to eliminate/minimize/reduce human error and streamline/automate/optimize weighing processes. From batching/portioning/dosing raw materials to verifying/inspecting/quantifying finished products, automated weighing solutions offer a range of benefits/advantages/features that cater/address/meet the demands/requirements/needs of modern businesses.

Furthermore/Moreover/Additionally, these systems often integrate/connect/interface seamlessly with other software/applications/platforms to facilitate/enable/support data analysis/tracking/management. This allows for real-time/instantaneous/immediate insights into weighing operations/processes/activities, leading/resulting/driving to improved/enhanced/optimized decision-making and cost/expense/budget savings.

- Ultimately/Concisely/In essence, automated weighing systems represent a significant/substantial/major leap forward in the field of weighing/measurement/accuracy.

- They/These/This technology is poised to reshape/transform/revolutionize the way we measure/weigh/quantify various materials and products, driving/fostering/encouraging greater efficiency/precision/effectiveness across industries.

Intelligent Load Scale: The Future of Unattended Weighing

The logistics industry is constantly evolving, seeking more optimized solutions to handle operations. One revolutionary advancement is the introduction of smart weighbridges. These cutting-edge systems offer a reliable and unmanned solution for weighing trucks, eliminating the need for manual involvement.

Smart weighbridges are equipped with technology that accurately measure the mass of passing vehicles. This information is then delivered to a centralized system for evaluation. The connection with programs allows for immediate monitoring, reporting of weighbridge performance, and creation of detailed reports.

The benefits of implementing smart weighbridges are abundant. They boost efficiency by minimizing wait times and manual work. Smart weighbridges also enable exactness in weighing, minimizing the risk of errors. Furthermore, they add to improved safety by monitoring vehicle movements and recognizing potential threats.

Ditch Manual Weighing: Embrace the Power of Automated Weighbridges

In today's fast-paced operational landscape, efficiency is paramount. Manual weighing processes can be inefficient, leading to delays and potential errors. To streamline your operations and enhance accuracy, it's time to shift to automated weighbridges. These cutting-edge systems leverage sophisticated devices to provide precise weight readings in real-time, eliminating the need for manual intervention. Automated weighbridges offer a range of perks, including improved accuracy, increased throughput, and enhanced safety.

- Furthermore, automated weighbridges can integrate seamlessly with your existing software systems, allowing for real-time data collection and analysis. This valuable information can guide you in making informed decisions regarding inventory management, production planning, and shipping.

- Implement the power of automated weighbridges today and experience a noticeable improvement in your operational efficiency and accuracy.